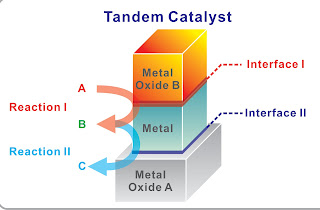

Currently, some 20 percent of the world's industrial production is based on catalysts — molecules that can quicken the pace of chemical reactions by factors of billions. Oil, pharmaceuticals, plastics and countless other products are made by catalysts.

Many are hoping to make current catalysts more efficient, resulting in less energy consumption and less pollution. Highly active and selective nanocatalysts, for example, can be used effectively in efforts to break down pollution, create hydrogen fuel cells, store hydrogen and synthesize fine chemicals. The challenge to date has been developing a method for producing nanocatalysts in a controlled, predictable way.

In a move in this direction, Yu Huang, an assistant professor of materials science and engineering at the UCLA Henry Samueli School of Engineering and Applied Science, and her research team have proposed and demonstrated a new approach to producing nanocrystals with predictable shapes by utilizing surfactants, biomolecules that can bind selectively to certain facets of the crystals' exposed surfaces.

Their new study can be found online in the journal Nature Chemistry.

"In our study, we were able to identify specific biomolecules — peptide sequences, in our case — which can recognize a desired crystal surface and produce nanocrystals exposed with a particular surface to control the shape," said Chin-Yi Chiu, a UCLA Engineering graduate student and lead author of the study.

"Facet-specific biomolecules can be used to direct the growth of nanocrystals, and most importantly, now we can do it in a predictable fashion," said Huang, senior author of the study. "This is still a first step, but we have overcome the challenges by finding the most specific and selective peptide sequences through a rational selection process."

Huang's team accomplished this by using a phage library that generated a pool of peptide sequences. The team was then able to identify the selectivity of peptide sequences on different crystal surfaces. The next step, the researchers say, is to figure out what exactly is happening on the interface and to be able to describe the characterizations of the interface.

"We don't know the molecular details yet — that's like the holy grail of molecular biomimetics," Huang said. "Take the catalyst, for example. If we can predict the synthesized catalyst for just one surface, it could have much more improved activity and selectivity. We are still in the initial phase of what we really want to do, which is to see whether or not we can eventually program the synthesis of material structures."

"It's always been a personal interest to learn from the natural evolutionary selection process and apply it to research," Chiu said. "It is especially satisfying to be able to engineer a rational selection process for nanoscale materials to create nanocrystals with desired shapes."

###

The study was funded by the U.S. Office of Naval Research; the U.S. Army Research Office, through the Presidential Early Career Award for Scientists and Engineers (PECASE); and a Sloan Research Fellowship.

The UCLA Henry Samueli School of Engineering and Applied Science, established in 1945, offers 28 academic and professional degree programs and has an enrollment of almost 5,000 students. The school's distinguished faculty are leading research to address many of the critical challenges of the 21st century, including renewable energy, clean water, health care, wireless sensing and networking, and cybersecurity. Ranked among the top 10 engineering schools at public universities nationwide, the school is home to seven multimillion-dollar interdisciplinary research centers in wireless sensor systems, nanoelectronics, nanomedicine, renewable energy, customized computing, and the smart grid, all funded by federal and private agencies.

Contact: Wileen Wong Kromhout wwkromhout@support.ucla.edu 310-206-0540 University of California - Los Angeles