Just as a gecko sheds its tail, metal-alloy particles endure 850 degrees Celsius by ditching weaker components, researchers report in Nature Materials

PITTSBURGH—A University of Pittsburgh team overcame a major hurdle plaguing the development of nanomaterials such as those that could lead to more efficient catalysts used to produce hydrogen and render car exhaust less toxic. The researchers reported Nov. 29 in Nature Materials the first demonstration of high-temperature stability in metallic nanoparticles, the vaunted next-generation materials hampered by a vulnerability to extreme heat.

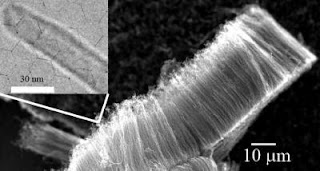

Götz Veser, an associate professor and CNG Faculty Fellow of chemical and petroleum engineering in Pitt's Swanson School of Engineering, and Anmin Cao, the paper's lead author and a postdoctoral researcher in Veser's lab, created metal-alloy particles in the range of 4 nanometers that can withstand temperatures of more than 850 degrees Celsius, at least 250 degrees more than typical metallic nanoparticles.

Veser and Cao present an original approach to stabilizing metallic catalysts smaller than 5 nanometers. Materials within this size range boast a higher surface area and permit near-total particle utilization, allowing for more efficient reactions. But they also fuse together at around 600 degrees Celsius—lower than usual reaction temperatures for many catalytic processes—and become too large. Attempts to stabilize the metals have involved encasing them in heat-resistant nanostructures, but the most promising methods were only demonstrated in the 10- to 15-nanometer range, Cao wrote. Veser himself has designed oxide-based nanostructures that stabilized particles as small as 10 nanometers.

For the research in Nature Materials, he and Cao blended platinum and rhodium, which has a high melting point. They tested the alloy via a methane combustion reaction and found that the composite was not only a highly reactive catalyst, but that the particles maintained an average size of 4.3 nanometers, even during extended exposure to 850-degree heat. In fact, small amounts of 4-nanometer particles remained after the temperature topped 950 degrees Celsius, although the majority had ballooned to eight-times that size.

Veser and Cao were surprised to find that the alloy did not simply endure the heat. It instead sacrificed the low-tolerance platinum then reconstituted itself as a rhodium-rich catalyst to finish the reaction. At around 700 degrees Celsius, the platinum-rhodium alloy began to melt. The platinum "bled" from the particle and formed larger particles with other errant platinum, leaving the more durable alloyed particles to weather on. Veser and Cao predicted that this self-stabilization would occur for all metal catalysts alloyed with a second, more durable metal. ###

Veser and Cao conducted their work with support from the National Energy Technology Laboratory, the lead research and development office for the U.S. Department of Energy's (DOE) Office of Fossil Energy, as well as the DOE's Office of Basic Energy Sciences and the National Science Foundation.

Contact: Morgan Kelly mekelly@pitt.edu 412-624-4356 University of Pittsburgh